Laser printers are a marvel of technology from which we sometimes find it difficult to discern how they work. Inkjet printers, although complex, have a behavior that we can «imagine». There is an injector that performs the functions of a brush and «paints» the ink on the paper that passes through it.Although much more difficult to put into practice than this example, it is something simple to imagine. But laser printers are another thing to sing. There is no ink but a magnetized powder that magically sticks to the leaf. Witchcraft!

We already have another article that explains in depth how a laser printer works with great detail, but there is an element that allows this «magic» and that perhaps deserves a somewhat more elaborate article. We are talking about the laser ambor t .

What is the laser drum and what is it for?

If we do not know what this device consists of, probably the first image that comes to mind is a group whose drummer is playing an instrument taken from the Star Wars movies . Hopefully, but nothing is further from reality. This device is inside our laser technology printers (hence the adjective) and has a cylindrical shape (hence the noun).

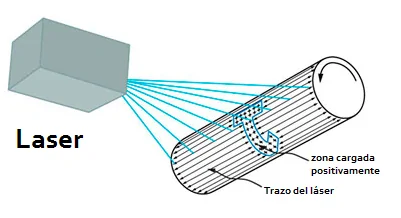

It is responsible for «picking up» the toner powder at specific points and transfer it to the paper later. This element of the printer rotates on itself while a beam of laser beams on it, positively loading it at the points where it is later desired that the printing is made. The powder of the toner has a negative charge, so when rolling the cylinder next to the toner, the ink powder particles (negatively charged) stick to the points where the laser has impacted (positively charged), remaining fixed. there. At this time the image to be printed will be arranged along the device. It’s not magic, it’s electromagnetism .

Laser drum

Subsequently, the opposite process will be carried out with the paper, which will be positively charged, attracting the dust particles of the cylinder. As we explained in a previous article, this powder will be fixed to the sheet by pressure and temperature. As we have seen, this device is an indispensable element in laser technology printers, as well as inkjet nozzles.

Types existing in the market

There are two basic types of drum: one that is integrated with the toner and one that is an independent part of it. The integrated brand is used as HP , while others like Brother have toners and cylinders independent of each other.

The advantages and disadvantages of both methods are obvious. In the first case every time we have to replace the toners we will also be changing the associated cylinder so we will not have to worry about replacing the cylinder itself, but at the same time we will incur more expense since each time it is spent « the ink »we also have to change an element that will probably still have a useful life. And is that this device to have photoconductive elements that are exhausted with the use has a limited lifeto a number of impressions that can be more or less high, depending on the model and quality.

In the second case we will need to change each time the cylinder is necessary and it will be more expensive to do it, both in money and in the fact of changing the piece itself. However, having to perform this operation sporadically will save money in the long run.

So, what kind of cylinder is suitable for our needs? We will see it in the next point of our list.

Duration and use

As with almost everything in the world of printers and computer science in general, the model we are going to use will depend on the final use we want to make of it. It does not make sense to buy a computer with the latest graphics card in the market and the fastest RAM available if we are going to use it to surf the Internet or play Minecraft. With lasers the same thing happens, if we are going to decide between a brand and another one for the type of cylinder that it possesses, before we will have to weigh the pros and cons previously exposed, and also the use that we are going to make of the printer.

If we are going to make a large number of impressions, the ideal is that the cylinder is integrated with the toner . As we have already mentioned in the long run, this will make the prints more expensive, but changing each certain number of them the cylinder along with the toner will guarantee that the quality of the prints is perfect.

If on the contrary we are going to make a low number of impressions it is better that toner and cylinder are separated, since the flow of impressions will not affect the cylinder so much and can be changed every time without it being considerably reduced The final quality of the printing.

Cylinder failures

As we just checked the condition of the cylinder directly affects the quality of the impressions we are making. With each new printing, the photoelectric elements of the piece wear out and lose their properties, with which they lose «resolution» points in the milder cases or even entire lines without printing in the most severe cases. If you see vertical lines in your laser prints do not hesitate, it’s time to change the cylinder.

If, on the contrary, vertical stains appear on the prints, it is very likely that the cylinder has been damaged in some way. It may have some small bump or dent, although they are usually exceptional cases since these items are very well protected inside the printer. It is more likely to have some kind of scratch caused by accumulated dirt . In these cases it is convenient to clean the dirt and the accumulated lint in the printer with great care not to damage the cylinder. This dirt is often environmental, but many other times – especially in those cases where the printers are better isolated – can be the result of poor quality paper that releases cellulose dust that is trapped inside the printer, forming these clogs and scratches in the cylinder.

A very different – and extreme – case is when the leaf comes out «in the negative». This implies that the electric charges that are being sent to the cylinder are changed, that is, what was wanted to «magnetize» has been left undone and what was wanted to maintain without «magnetizing» has been charged with static electricity. It is terribly strange and often tends to be more indicative of printing software failures or human errors than cylinder failures, but it does not hurt to keep it in mind. More common is when the blade comes out completely in black : this indicates a clear failure of the cylinder in which it is completely magnetized, and its replacement is necessary.

Now we know something more how this indispensable element of our laser printers works, and knowing the use you want to give it, you can also decide if it is better for you to use an integrated toner or an independent one.

- Epson Expression Photo XP-8700 | Análisis y Opiniones - 6 julio, 2022

- HP LaserJet M110we y M110w | Análisis y Opiniones - 23 junio, 2022

- HP Color LaserJet Enterprise M554dn | Análisis y Opiniones - 10 marzo, 2022

A4toner: Cartuchos de tinta, toner e impresoras

A4toner: Cartuchos de tinta, toner e impresoras